After Removing The Valve Body On A A604/41te, Can You Service The Low And Reverse Accumlators?

41TE, 42LE, A-604, and more: Mopar four-speed automatics based on the Ultradrive

Chrysler Corporation used three families of four-speed automatic transmissions:

- Jeep used Borg-Warner four-speeds, a legacy from AMC.

- Contrivance trucks and some Jeeps used a 4-speed which added an overdrive gear to the existing A-999 iii-speeds.

- Chrysler, Dodge, and Jeep used versions of a revolutionary (in 1989) new four-speed automatic, originally coded A-604 but subsequently bearing the names 40TE, 41TE, 42LE, and then on.

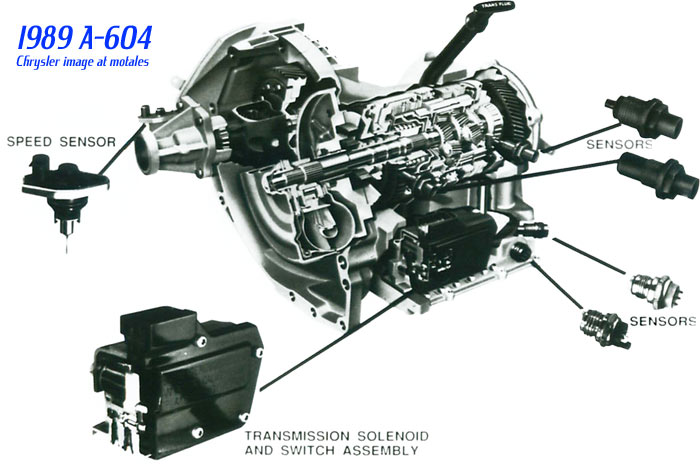

The Ultradrive was created specifically to be controlled by a figurer; it jettisoned bands for solenoids which could activate clutches without clutch valves. It was the beginning transaxle in the world with completely electronic control, and was revolutionary but poorly tested when launched on the 1989 models.

Automatic transmissions for cars and minivans: A-604 / Ultradrive

The "Ultradrive" (officially coded A-604) had been in development for years, waiting for materials and computers to catch upward to the designers' vision, when it was launched in 1989. Even and so, it was non fully tested when the first automatics were bolted into loftier-end cars and minivans. Chances are few outside of Consumer Reports would have really noticed the problems if it had been restricted to cars in its start few years, but information technology was put into minivans from the beginning. A transmission that works reasonably well in cars—and it was still somewhat problematic in that location—was a far bigger problem in minivans, which were heavier than cars—and were ofttimes packed with seven or eight people and their baggage.

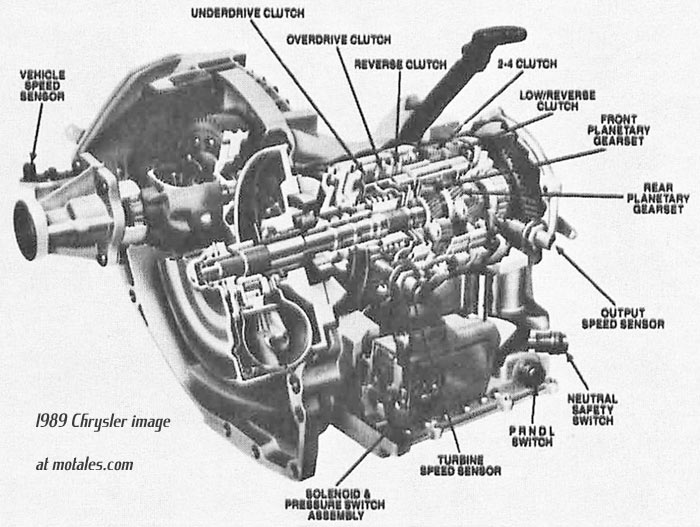

The Ultradrive directly controlled clutches with pulse-width modulated solenoids, which fabricated a loud and distinctive ratcheting racket as they worked. The direct action fabricated the valve torso much simpler, and eliminated clutch valves, sprags, and roller clutches. V clutch packs handled all the ratios (Low/Contrary, Underdrive, Overdrive, two/4, and Reverse); the bodily gears were the usual Simpson planetary design, with hydraulically applied clutches.

The computer directly controlled shifting, so each shift was fabricated based on engine data, velocity, and the gas pedal position. Fifty-fifty the 1989 Ultradrives adjusted for personal driving style and mechanical or fluid article of clothing. A preprogrammed "limp domicile" mode allowed driving in starting time, 2d, and contrary if sure sensors failed, preventing greater damage and making sure the possessor took the vehicle in for repair, instead of driving around with the Bank check Engine low-cal on. (Another manufacturers would brand it impossible to start the vehicles in this case.)

The Ultradrive was smaller, lighter, and simpler than competing iv-speed automatics—and had better performance. It should have been a home run. Famed Chrysler and Ford projection leader (known for aluminum Prowlers and F-150s and the Ford GT) Chris Theodore said, "It was a neat idea. It was clutch-to-clutch shifting. No under and over clutches, fewer parts, electronic control, but the prior VP of engineering had decided to bet the farm, and they put it into all the Chrysler models at once. Usually when y'all beginning out with new engineering science you desire to get a little field feel and brand sure all the bugs are out."

There was pressure on the executives, to be off-white; other companies had minivans with four-speed automatics and bigger engines. Still, nobody wanted a minivan that might have a transmission replacement ii months later on it was built.

Chris Theodore said, "We had a proficient team of engineers, simply there were just literally hundreds and hundreds of bugs. We but started banging abroad and banging away cut them downwardly and knocking them down one at a time." Problems came from engineering, suppliers, and manufacturing. Week by week, they were eliminated.

One result was the transmission fluid. Dexron Two was not glace plenty and was too thick when cold; other properties were also wrong for the new automatics. Chrysler used its own fluid, ATF+3, but kept telling customers they could use Dexron if ATF+3 was not bachelor. Dealers and mechanics and owners seem to have causeless this meant ATF+3 was basically a money take hold of; one transmission repair store told me that they were virtually to give up on the transmissions when, in 1999, reading a story on Allpar, they decided to try using ATF+iii. Their repair charge per unit immediately dropped to normal. A single quart of Dexron could cause serious problems. Eventually, ATF+three was replaced past ATF+4; and Chrysler stopped writing that Dexron was acceptable.

All these transmissions were fabricated at the Kokomo (Indiana) circuitous. The later 62TE was based on the same design, but had two more forward gears.

"Non Ultradrives"—40TE, 41TE, 42LE, and 42RLE

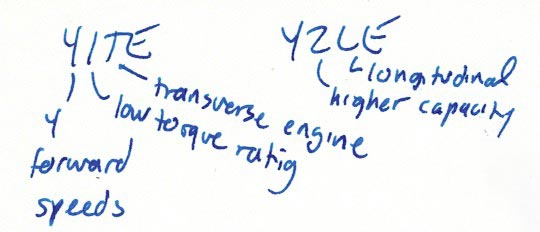

The 41TE was essentially an A-604 with a new lawmaking.

The new 42LE was derived from the 41TE to support a new set of large cars, using front end wheel drive with longitudinal (n-s) mounted engines. The "LH cars" used a revised version of the 41TE (originally A-606) which could likewise handle more than torque, since the top LH engine put out 214 horsepower—well above the visitor'southward highest output V6 before that fourth dimension. The transmission variant was coded 42LE—4 gears, 2d torque rating, longitudinal mountain, electronic controls.

The 42LE's "beefing up" were mainly in the final drive unit of measurement. Information technology had higher capacity center-section components, upgraded clutch packs, and barreled axle shafts; to quiet down the characteristic rattling when changing gears, they integrated the solenoid pack into the transaxle, though that made service a flake harder. The torque converter had a longer input shaft.

The 42LE did not replace the 41TE, which was used for many years afterwards; indeed, the 41TE was added to the Neon in 2002.

| R | 1 | ii | 3 | 4 | |

|---|---|---|---|---|---|

| Gearing | 2.21 | 2.84 | ane.57 | 1.00 | 0.69 |

The 42RLE was essentially the 42RE only adapted for rear bicycle drive utilise (that's the "R" in the championship). The basic changes were obvious—taking out the differential and transfer chain, and resizing the case. The commencement and second gear ratios were likewise changed slightly. The transmission was developed originally for the 2003 Jeep Liberty, Jeep Wrangler, and Dodge Ram V6; but it ended up in nearly every rear cycle drive machine the company made for a while, including the 2009 Contrivance Challenger (V6), the Dakota, and the Durango. The 42LE had a transfer chain to motion power to the transfer shafts, eliminating the transfer gears; and it combined the transfer chain encompass and rear transaxle embrace into a single unit.

Other variants

The 40TE, starting in the 2003 model year, was a lighter version of the 41TE, with the aforementioned gear ratios; information technology was also reputedly cheaper. Information technology debuted in the PT Cruiser, Sebring, Stratus, Neon, and, oddly, given its weight, the Caravan. Choosing too low a torque capacity may have resulted in more transmission failures, particularly on the PT Cruiser and Caravan.

The 41AE, usually referred to as a 41TE despite the different designation, was used for all wheel drive minivans and Pacificas from 1991 to 2008 (minivan utilize ended in 2004 but the Pacifica crossover, based on minivans, ran from 2004-08).

The TES versions (40TES, 41TES) of the 41TE and 40TE were smaller, and so they could fit into the 2007-10 Chrysler Sebring. The principal changes are making the bell housing and torque converter smaller. The 40TES, having a low torque rating, was used with 4-cylinders; the 41TES with half-dozen-cylinders. The "TES" transmissions used variable line force per unit area (see beneath), which required a pressure level sensor and line pressure solenoid to exist added to the valve trunk. They were used on the Sebring (later on renamed 200), the Avenger, and the Journey.

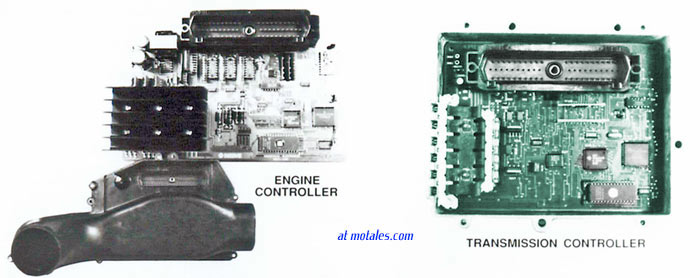

Manual estimator

The computer had direct inputs from the battery, ignition (run), cranking, throttle position, engine speed, turbine speed, output speed, depression/reverse pressure switch, 2-4 pressure switch, overdrive pressure switch, and manual valve lever position sensor. It also took information from a bus: target idle speed, coolant and ambient temperature, restriction position, engine speed, cruise command status, manifold pressure, and engine/trunk identifiers. In one case it was done with its calculations, it sent information to the PRNDL (which was digital, not mechanical), the transaxle relay, solenoid pack, speedometer, and, with the 3.5 engine, engine torque management system. It besides output error messages to the DRBII. The computer limited reverse speed to 8 mph, and controlled the "limp manner."

The system estimated transmission fluid temperature and adjusted shifting when it was cold, and increasing torque converter lockup when it was hot. The organisation estimated estrus added by the torque converter and parasitic losses, subtracting heat removed past the fluid cooler and ordinary radiation. At the manufactory, the transaxle computer measured and stored the amount of fluid needed to fill up each element during shifts, to preclude random variation in volume from causing poor shifts.

Because they adapt to driving mode, they can act a fiddling confused when moving from one driver to another. In one case the preparation period is over, they adapt to the driver's desires. Cars shared by ii people with different driving styles can exist problematic in terms of odd shifting; Chrysler never linked transmission profiles to commuter memory in cars that had it.

In 1995, the transaxle could modulate hydraulic pressure 143 times per second during a shift—making 14 adjustments in the fourth dimension it takes to glimmer. The software on the transmissions could be upgraded with a "flash" using dealer equipment; numerous such "flashes" were issued over the years.

Lockup torque converters

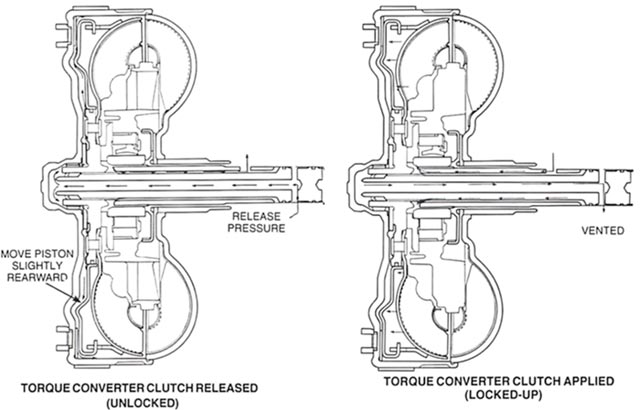

All the Ultradrive-style automatics had lockup torque converters, merely what is a lockup torque converter?

In a normal torque converter, a sort of fan spins thick oil around. A second sort of fan, connected to the axle, picks up the spin from the movement of the oil. This is done largely because it lets the transmission move at a unlike speed from the engine—so when the car is stopped, the engine can idle while the manual is non moving. (If the car sits like that for a long fourth dimension, the fluid gets quite hot, because it'south beingness stirred on i side while the other side does not move, causing a great deal of friction. That'due south why it's all-time to shift into Park, which lets the transmission gears spin around, when idling for more than a few minutes.)

The fluid link is much smoother than a direct connection, merely has a problem: when the engine and transmission are both moving, some ability is lost through the fluid. The connection between the powered fan and the unpowered fan is not 100%. The solution is to have a mechanical link to demark the engine to the transmission when possible, instead of sending power through the fluid. Chrysler originally used a fluid-controlled clutch to practise this, locking up only in third gear, and nether sure weather condition. The Ultradrive, as one might look, used a estimator-controlled clutch. The original UltraDrive (A-604) and 41TE automatics allowed the lockup in third and fourth gear, between 27 mph and 50 mph, under various conditions; in some cases 2d gear could lock upwards, too. What'south more, the computer could bind the clutch more gradually if needed. The mechanical connection was released when the driver coasted (no throttle) or when gears were changed. It could experience similar another shift, disruptive drivers who were counting gears. In any case, the lockup converter could raise economy by upwardly to iii%.

4-speed automatics: Changes over time

The ATF+3 transmission fluid was replaced in the 1999 model twelvemonth by ATF+4. This allowed the transmissions to go a "make full for life," thank you to the synthetic-base fluid's superior resistance to heat damage.

Fifty-fifty afterwards the crunch of 1989-91 passed, engineers kept changing the four-speed transmissions to increase durability, comfort, and efficiency, and to cut noise; their efforts never ceased.

In 1994, to extend the life of the transmissions in minivans—both their toughest application and possibly their virtually of import—engineers started cutting engine output during shifts, calling it "torque management." Before shifting, the transmission computer would tell the body reckoner, which changed the spark advance to reduce output. The system worked; a more than elegant solution, cutting fuel commitment, took its place in 1996. That could cut engine torque past 50% during the shift.

The manual was called into play for overspeed reduction, part of cruise command. If the manual was in overdrive (fourth) and the speed was more than 4 mph over the set up point with a closed throttle (foot off the gas pedal), the computer downshifted the transaxle to third, and waited until the cruise controller opened the throttle by at least 8° before upshifting again. If the driver cancelled the cruise control, the transmission would still keep the lower gear until half a 2nd subsequently the driver opened the throttle past 8°, in case the commuter needed more than ability.

During the 1997 model year, fluoroelestomer seals were phased in; these were more durable than the original material. The pump housing seal was switched to Polyacrylate on March 14, 1996. The pump'southward confront and outer tip clearances were reduced in Nov 1998 to stop delayed engagement issues, which had caused "lawmaking 35" to exist ready.

The valve body gained a opposite-vent reservoir check valve to reduce overdrive clutch wearable in 1999. The rear annulus gear was upgraded on February 19, 1997. The splines on the forepart carrier were induction heat-treated starting around 1999 (this may crusade the forepart carrier to expect "rut damaged"). The rear carrier was upgraded to a v pinion blueprint, and the forepart dominicus gear had a stronger weld. A new overdrive shaft and reaction shaft support were upgraded for immovability.

Transmission range sensors were revised in late 1998 for reliability; considering they had a larger connector body, the case had to exist inverse, and replacing earlier sensors may crave a special seal. The new connector also switched from pins to blades.

In 1999-2000, a new solenoid/pressure switch assembly with fewer internal parts was phased in; it was quiet plenty to eliminate a sound shield. Input and output sensors were also upgraded considering some customers had open circuit mistake codes. V6 minivans also gained an upgraded, two-piece differential for better strength and lubrication.

Variable line pressure (VLP) was phased in starting in 2006, reaching all transmissions in model-year 2007. The first transmissions to get VLP were coupled to the 3.vii liter V6 (trucks and SUVs) and the Sixty cars' 2.7 liter V6. Variable line pressure ways that the manual adjusts its internal fluid pressure, cutting parasitic losses from the pump and hydraulic system. That increases gas mileage and improves durability.

Technical transmission talk

Transmissions had an identification label; the starting time letter of the alphabet was K (Kokomo), followed by the last three digits of the part number; the build date (four digits, based on a 10,000 day internal calendar, so 3843 would exist the 3843rd day of production), and the build sequence number.

The transmissions used cast aluminum cases and stamped steel oil pans, and had clutch pistons activating the torque converters. They had separate sumps for the transaxle and differential. Valve bodies used five valves, with no governor or throttle pressure level; equally stated earlier, shift valves were replaced by solenoids. A manual valve lever position sensor, attached to the valve body and submerged in fluids to eliminate a noise shield, operated the reverse lights and starter relay, eliminating three switches.

As for the clutches, according to Chrysler:

- The underdrive clutch is in front of the input clutch retainer.

- The overdrive clutch is the center clutch in the clutch assembly.

- The reverse clutch is in the back of the input clutch assembly and uses the same piston, pressure plate, and belleville spring as the overdrive clutch.

- The 2-four clutch is behind the input clutch assembly.

- The depression/reverse clutch is in the back of the transaxle instance behind the ii-4 clutch.

The 2-4 and depression/reverse clutches share a reaction plate. The planetary gears are within these clutch assemblies and behind the input clutch; the front sun gear is welded to the center of two hubs. The rear lord's day gear is in the center of the rear carrier, and the front sun gear is in the center of the front end carrier. The rear carrier assembly includes the rear planetary carrier, front annulus gear, and output shaft. The transfer shaft had 33 teeth; the output shaft had 32 teeth. The transmission computer was behind the battery on the left fender.

The torque converter had three elements and a 2.65 stall torque ratio; the converter clutch was reckoner controlled.

Cars with these transmissions used an output speed sensor (rather than a straight speed sensor), with the body computer computing actual speed, saving parts and increasing accuracy. The trunk estimator could exist reprogrammed by dealers to compensate for changes in wheels and tires.

The shifter had roller detents corresponding to transaxle lever detents, and rubber isolators at the transaxle and the shifter to cutting vibration. A cable machinery locked the steering column and ignition key when not in Park; another cable kept the lever in Park unless the restriction pedal was pressed.

Repairs and problems

For years, the transmissions had no gasket between the transfer plate and valve body/accumulator housing; they were sealed by a steel separator plate instead. This could crusade harsh downshifts and gear engagements if in that location was a leak. RTV does non work as a sealant in this application; "Indian head shellac," according to one report at Allpar, does. Allpar noted they had non tested this, and we have not, either.

The most unremarkably needed repair is a fluid replacement, with ATF+4 (which replaces ATF+3).

While the transmissions were not meant to exist repaired past stop users, and the solenoid packs are not meant to be cleaned or rebuilt by amateurs, a skilled amateur can in fact solve many problems by cleaning and rebuilding the solenoid packs and screen filters; Allpar has details.

Books by MoTales writer David Zatz

This Mopar motorcar history site is copyrighted © 2021-2022 Zatz LLC. Contact us.

After Removing The Valve Body On A A604/41te, Can You Service The Low And Reverse Accumlators?,

Source: https://www.motales.com/engines/transmissions/ultradrives.php

Posted by: skipperfringuaing.blogspot.com

0 Response to "After Removing The Valve Body On A A604/41te, Can You Service The Low And Reverse Accumlators?"

Post a Comment